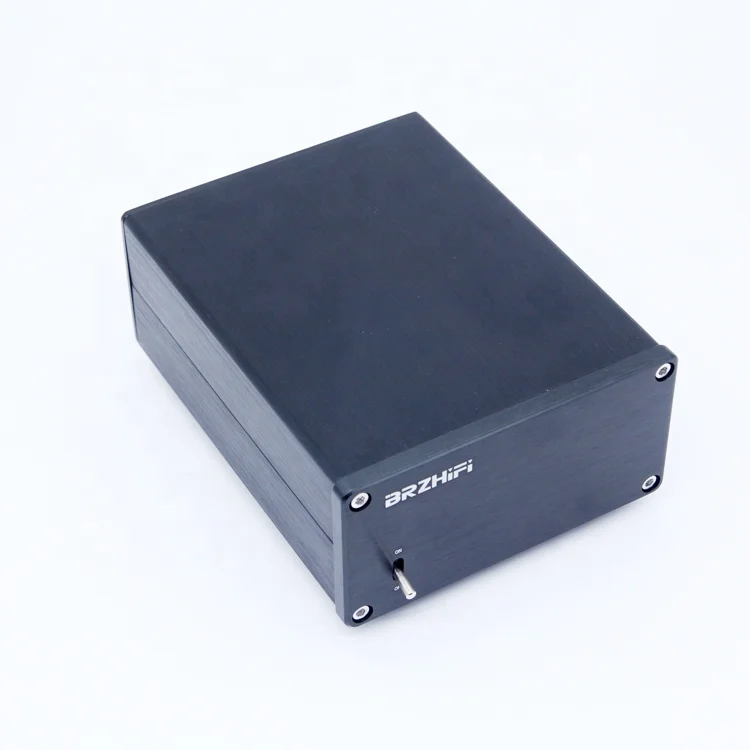

cd players manufacturer

A CD players manufacturer represents a specialized entity dedicated to the design, production, and distribution of high-quality compact disc playing devices. These manufacturers combine precision engineering with advanced audio technology to create reliable playback systems that deliver exceptional sound quality. Modern CD player manufacturing involves sophisticated production lines equipped with state-of-the-art testing facilities, quality control measures, and automated assembly processes. These facilities typically incorporate advanced surface-mount technology for circuit board assembly, precise laser calibration systems, and rigorous testing protocols to ensure optimal performance. Manufacturers focus on developing players with enhanced features such as anti-skip protection, digital signal processing, and multiple format compatibility including CD-R and CD-RW support. They also integrate various audio output options, from standard analog connections to digital optical and coaxial outputs, catering to different audio system configurations. Professional CD player manufacturers often specialize in both consumer and commercial-grade equipment, offering solutions for home audio enthusiasts, professional DJs, broadcasting stations, and commercial installations. The manufacturing process encompasses everything from component sourcing and assembly to final quality assurance, ensuring each unit meets strict performance and reliability standards.