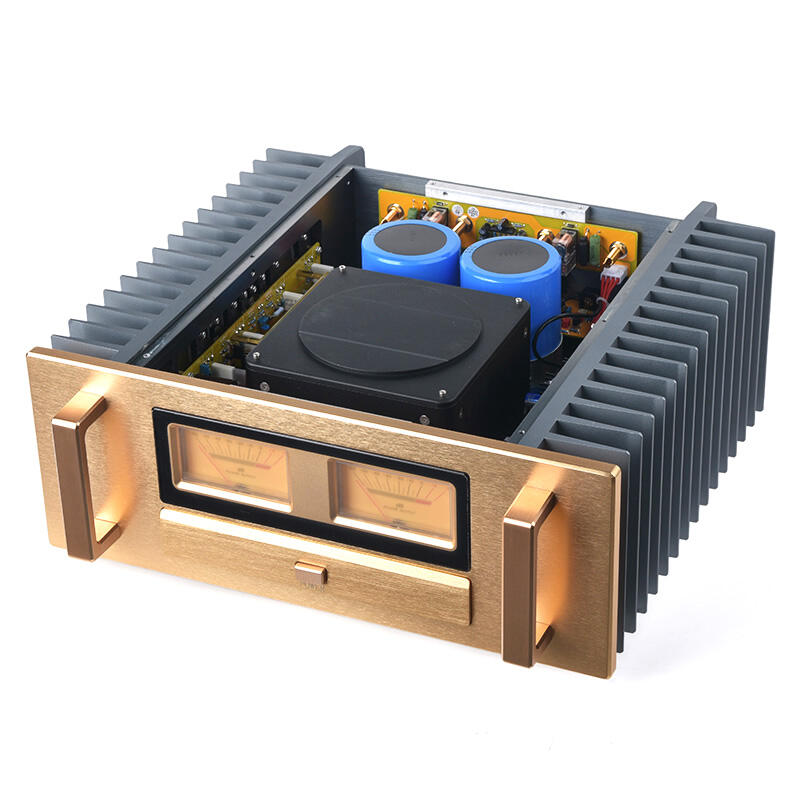

power amplifier factory

A power amplifier factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality power amplification solutions for diverse applications. These facilities integrate advanced production lines, automated testing systems, and precision engineering processes to create reliable and efficient power amplifiers. The factory incorporates multiple specialized zones, including research and development laboratories, SMT assembly lines, testing chambers, and quality control departments. Each area is equipped with cutting-edge technology and staffed by skilled engineers and technicians who ensure the highest standards of production. The facility utilizes sophisticated manufacturing techniques, including surface mount technology (SMT), automated component placement, and precision soldering systems. Quality control measures are implemented at every stage, from component selection to final product testing, ensuring each power amplifier meets rigorous performance standards. The factory's capabilities extend to producing various power amplifier types, from small-signal amplifiers to high-power units, serving industries such as telecommunications, broadcasting, medical equipment, and consumer electronics. Environmental control systems maintain optimal temperature, humidity, and dust-free conditions necessary for sensitive electronic component assembly.